3D Printing: Next-Level 3D Production Prototypes & Production Parts

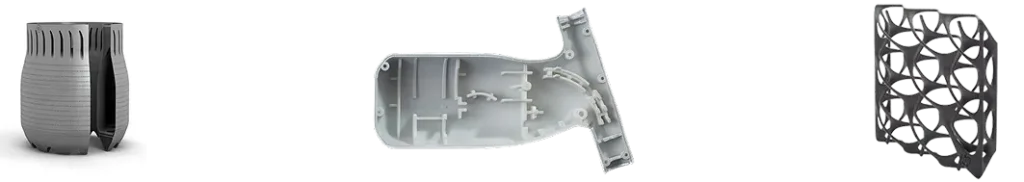

Our next-level 3D printing capabilities provide everything you need to move from design to reality. With MJF, SLS, SLA, and FDM technologies, we offer fast prototyping and durable, high-quality production parts to meet your exact requirements.

Start A New 3D Printing Quote

SolidWorks (asm, sldasm, part, sldprt) STEP, STL, IGS, Autodesk Inventor (.iam, .ipt), PDF, PNG, JPEG, DXF

3D Printing: Next-Level 3D Production Prototypes & Production Parts

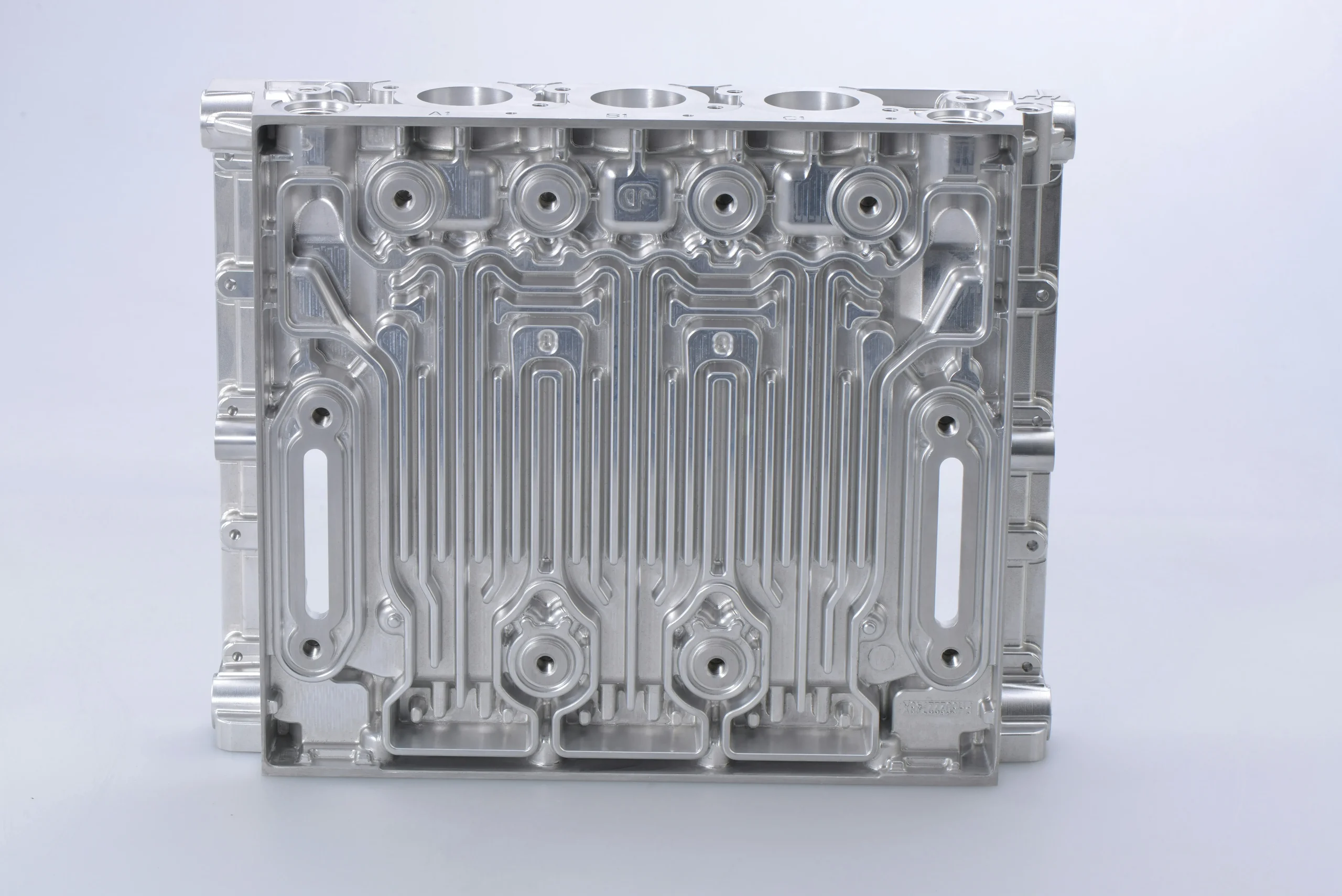

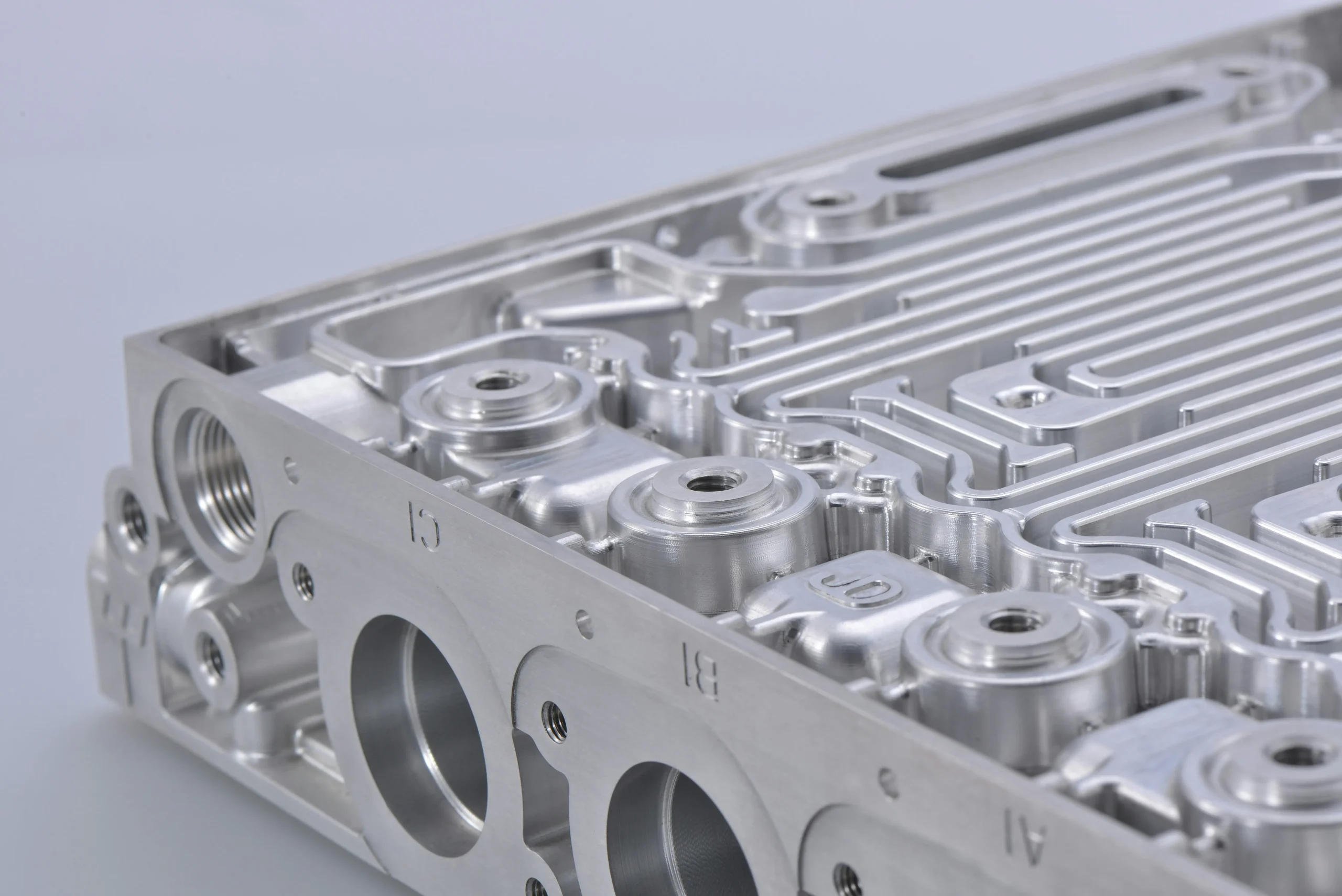

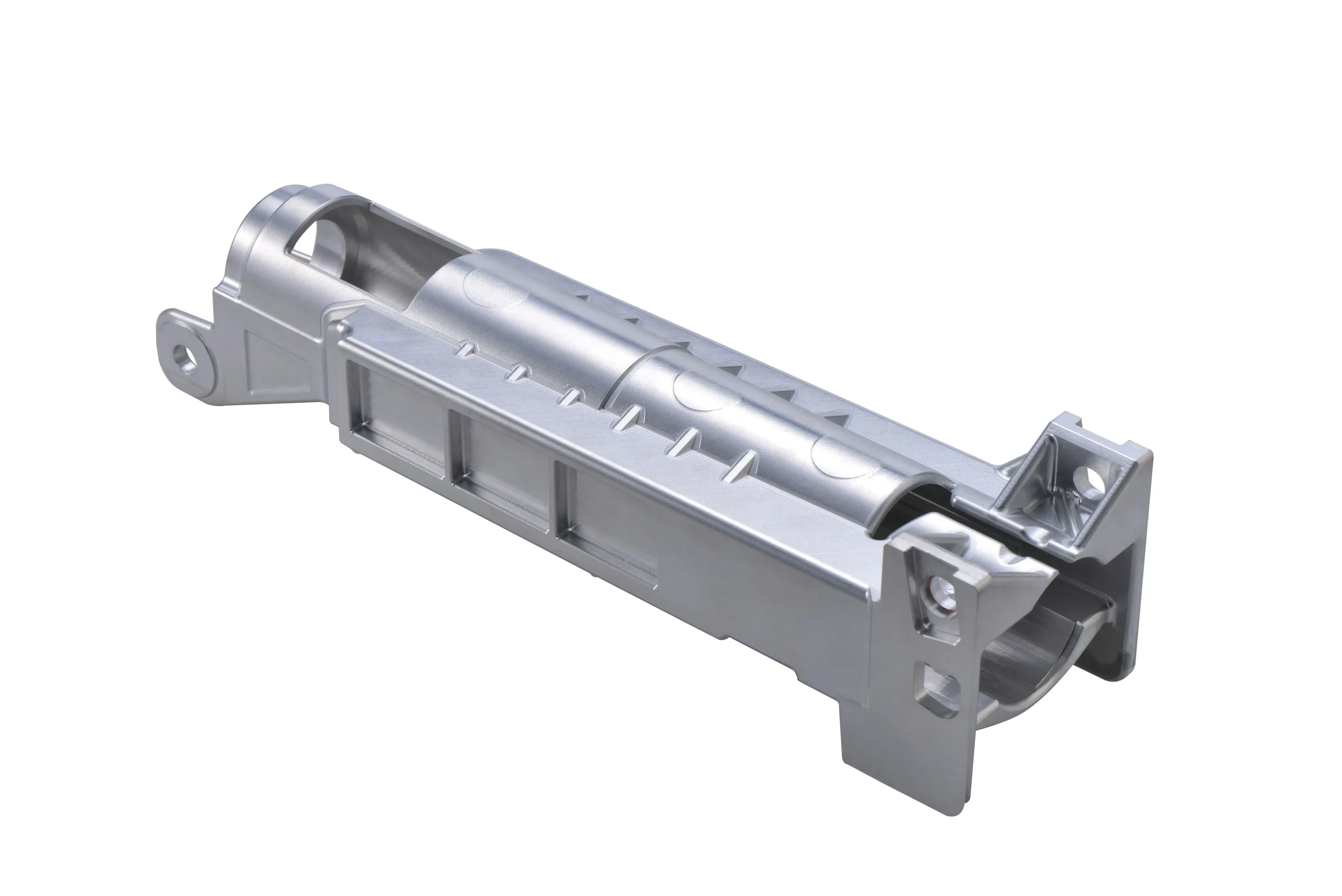

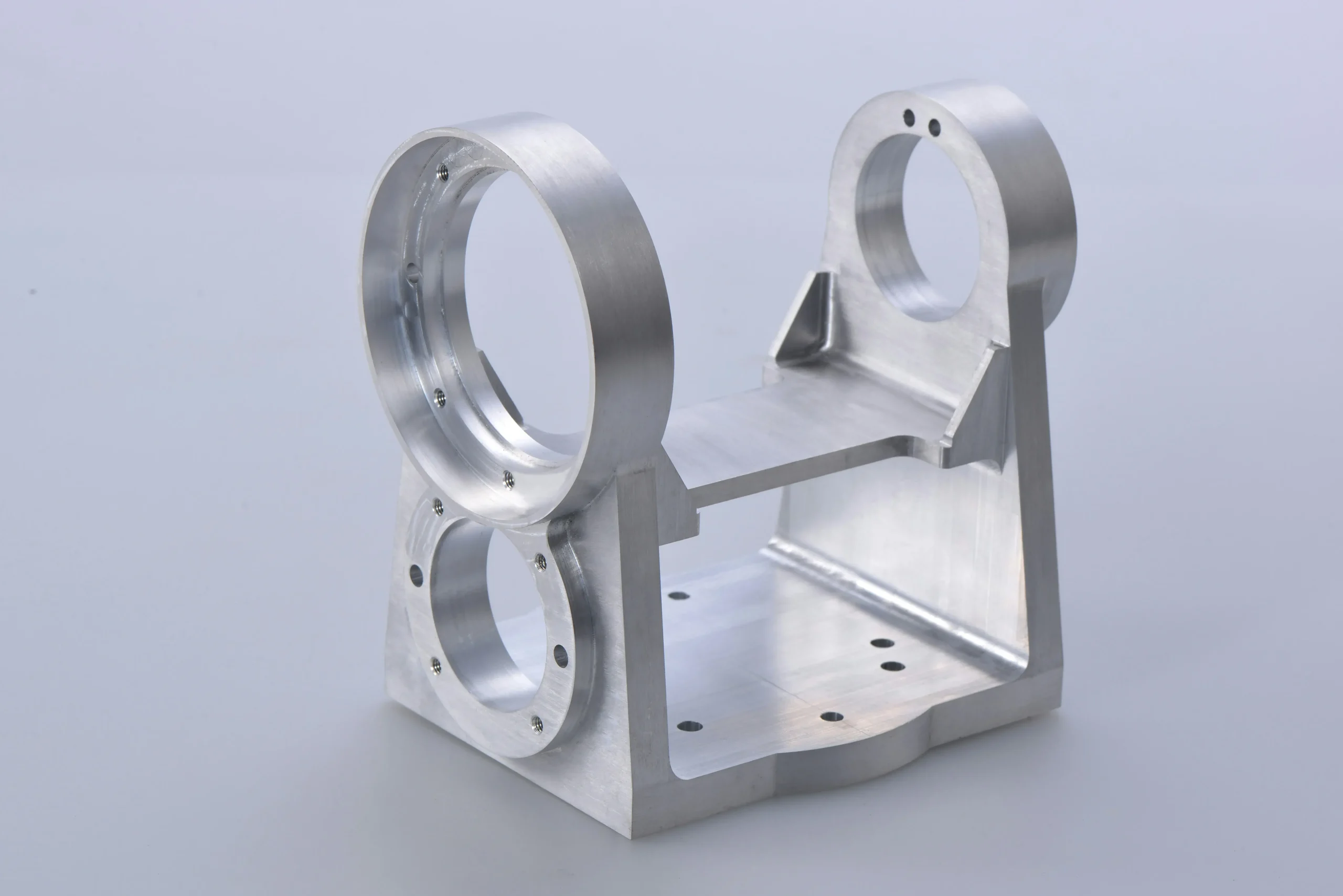

Unlock the power of modern manufacturing with our professional 3D printing services. We specialize in creating high-precision prototypes and durable end-use parts using advanced FDM, SLA, and SLS technologies. Whether you need a one-off prototype for testing or a small batch of production parts, we deliver consistent quality, fast turnaround, and a wide range of materials tailored to your needs.

From concept to creation, our team ensures every detail is accurate and production-ready. Experience the benefits of cost-effective, flexible, and on-demand manufacturing – perfect for industries such as engineering, architecture, product design, and more.

Get your ideas off the screen and into your hands – with next-level 3D printing.

Key Aspects

We deliver exceptional accuracy and fine detailing, ideal for functional prototypes and complex parts with tight tolerances.

Choose from a wide range of materials like PLA, ABS, PETG, Resin, Nylon, TPU, and more — each suited to specific performance needs.

Our streamlined process ensures quick production without compromising quality, helping you meet tight deadlines with confidence.

Whether you need a single prototype or a batch of production parts, we scale efficiently while maintaining consistent results.

Our 3D printing solutions are designed to meet the highest standards of precision, speed, and flexibility. We combine advanced technologies with a wide selection of materials to deliver outstanding results for both prototypes and end-use parts. Whether you need one piece or hundreds, our process ensures consistent quality, fast turnaround, and full support at every stage of production.

Procedure for Providing Services

We follow a streamlined, client-focused process to ensure the best results for every project. It starts with file preparation and material selection based on your needs. Once approved, we move to 3D printing using advanced equipment. After printing, each part undergoes careful post-processing and quality checks to meet all specifications. We then pack and deliver your parts, ready for use or further integration. Clear communication and precision at every step – that’s our approach.

We start by discussing your project goals, technical requirements, and ideal material options to ensure the best approach for your needs.

Your 3D files are checked and optimized for printing — ensuring proper scaling, wall thickness, and printability for accurate results.

Based on the application, we help you choose the best-suited material, balancing strength, flexibility, detail, and cost.

We print your parts using advanced 3D printers, followed by thorough quality checks to ensure dimensional accuracy and flawless surfaces.

After printing, parts are cleaned, cured, or finished as needed, then carefully packaged and delivered to you — ready for use.